Showing posts with label Project Administration. Show all posts

Showing posts with label Project Administration. Show all posts

Saturday, June 22, 2013

Rethinking the Cost of Time

Building design and construction have been governed in modern history by

our perception of time as a cost-based commodity. Both design

and construction are assumed to have greater competitive value if

production time is minimized. The first cost is generally lower if it

takes less time to design and build a project. We can

recognize an inverse relationship between first cost and long term cost when we

consider building products (e.g., cheap windows vs. expensive windows),

where lowest first cost may lead to higher long term costs in energy

usage, maintenance, and replacement. Yet, as a profession and an

industry, we have not been able or willing to recognize the long term value

of time invested in design and construction, such that more available

time (if well managed) results in more integrated attention to systems

and details that enhance long term building performance and optimize

long term operating costs. This issue is most notable in our continuing

willingness to commit to abbreviated time periods for design and

construction. We talk about the value of high performance buildings in

terms of energy efficiency and healthful environments, yet the market

continues to demand speed over performance due largely to the long

established premise that "time is money" - a premise that is reinforced

by the owner who wants the building quicker and by the designer and

contractor who must bid low to get the job and then minimize time in

order to avoid loss. When minimizing time is the highest priority, long

term performance may suffer. Owners, designers,

and contractors need to rethink the cost (and focus) of design and

construction time as they relate to long term building performance. We

have come to recognize long term risks associated with fast food; fast

design and construction deserve similar consideration.

Sunday, February 26, 2012

Planning a Phased School Renovation and Expansion

School renovation and expansion projects are commonly related to overcrowding and/or obsolete facilities. Construction in phases may be the only choice when school operations must continue in the same building or on the same site during renovations and expansion. Phasing needs and requirements should be considered during the design of such a project in order to ensure that provisions are adequate for ongoing school operations during each phase of the project.

Phasing plans and specifications should be based on at least the following considerations:

1. Each phase should provide sufficient classroom space for the enrollment. It may be necessary or advisable to rent or purchase relocatable modular classroom units for use during one or more phases of the project. The actual determination of necessary classroom count should be made by the school authority.

2. Construction areas must be adequately separated from occupied areas.

a. Separation walls may include a combination of existing walls or partitions and temporary or permanent new construction that affords the required fire separation and minimizes dust, fumes, and noise transfer from construction areas to occupied areas[1]. It also, of course, must adequately separate construction personnel from building occupants.

b. Construction fencing should be planned to separate contractor staging and construction areas from owner/user areas, neighboring properties, and public areas (e.g., streets and sidewalks). The fencing layout may need to change from phase to phase.

3. Utilities should be adequate and uninterrupted[2] in the occupied areas of the building. These utilities would typically include heat, lights, power (normal and emergency systems), telecommunications, water, sewer, fire protection and alarm systems.

a. Replacing boilers in a school can take as long as six months, especially if hazardous materials removal is part of the process, so the heating season should be considered when determining project phasing and the feasibility of replacing a heating plant in the existing location. It may be more practical to construct a new boiler room in order to minimize downtime and the risk of delays.

b. In order to maintain existing electrical services, it may be necessary to build a new electrical service entrance and backfeed the existing systems that will continue to serve existing occupied areas[3]. These backfeeds may be different for each phase of a project.

c. Any of the utilities may need temporary connections, extensions, routes, “jumpers”, supports, and/or temporary equipment in order to satisfy the need for adequate and uninterrupted utilities in occupied areas[4].

4. Adequate exits (i.e., egress facilities) must be provided. Exits must be adequate in width and arrangement to meet applicable code requirements. Exit calculations should be performed to determine code compliance. If any existing exits will be blocked by a phase of construction, the remaining exits must be sufficient in arrangement and width to meet code requirements[5], or additional permanent or temporary exits must be provided. Exit signage and lighting must also be coordinated with the exit arrangement for a given phase. Temporary[6] corridors may be necessary to link occupied parts of a building that are separated by construction areas. Protected exit walkways may be necessary to link building exits to the public way and maintain separation from construction areas.

5. Toilet facilities must be adequate to serve the occupied areas of the building. In some cases, this may influence the delineation of phases or the location of new toilets.

6. The need for food service must be addressed throughout phased school construction. Food preparation, service, and dining areas may need to be relocated to accommodate renovation and/or new construction. The challenge is reduced if food is typically prepared in a remote facility and delivered to the school undergoing renovation, but the challenge may be greater if the school undergoing renovation houses the main kitchen for several schools in a district. Can a temporary source or provider be arranged to prepare and deliver adequate meals? And, if the cafeteria itself must be offline for renovation, can an alternative space be used?

7. Athletic facilities use tends to vary seasonally. It may be practical to take a gymnasium offline during the months when physical education and other athletic programs can be accommodated outside. This consideration may influence the phasing schedule such that gymnasium renovations occur during warmer months; and field improvements may need to be completed during summer vacations or planned such that new fields are completed before existing fields are improved or taken offline.

8. Parking must be maintained or provided in sufficient quantity and condition to serve the building occupants. The parking arrangement may need to be changed from phase to phase to satisfy the requirement. Walkways must be included to connect parking areas to building entrances. Parking areas for building users should be separate from construction parking areas.

9. Separate driveways should be planned for building users, school buses, and construction. The typically desirable separation of school buses from cars should be part of each phase, and a separate vehicle entrance to the site should be planned for construction personnel and deliveries.

10. Air intakes must be protected from dust and fumes. Temporary air intake “stacks” may be necessary at building air intakes adjacent to construction areas to avoid contaminants related to construction.

11. Accessibility features that are required for the school facilities must be maintained as part of each phase[7]. These would include, for example, ramps and elevators to the extent required.

Timely phasing considerations are likely to influence a project design in ways that will make construction less disruptive for building occupants.

The requirements related to phased construction should be clearly established on the drawings and in the specifications that will be used for bidding and constructing the project.

[1] Special requirements applicable to hazardous material removal may be more stringent and take precedence over general criteria based on desirable separation. Also, the EPA has published indoor air quality (IAQ) guidelines for school renovation (see http://www.epa.gov/iaq/schooldesign/renovation.html), and states and other authorities have established similar criteria.

[2] Contract documents may provide for necessary, brief or momentary interruptions to occur during power switchovers and similar changes. If they are necessary during occupied hours, they should be scheduled in advance with the building owner.

[3] Local fire authorities typically want to limit electrical services to a single location where power to an entire facility can be shut off in order, at least in part, to minimize risk to fire fighters.

[4] Special attention is warranted where partial building demolition will sever the services or structural support of services between occupied building areas. The bid documents should be clear in requiring temporary support or temporary rerouting of utilities and/or temporary equipment to serve the remote areas.

[5] The applicable code should be studied to determine whether any reduction in egress capacity is allowed, even in the case where existing exits exceed code requirements.

[6] The applicable code should be studied for requirements and limitations related to “temporary” construction. The duration of such construction may be limited by code to less than the anticipated duration of use during phased construction. For example, Section 108 of the 2009 IBC limits a permit for temporary structures and uses to 180 days; yet some requirements for temporary structures are not less than what is required for permanent construction. Chapter 31 of the 2009 IBC also includes requirements for temporary structures and for special construction that may be considered applicable to temporary facilities for phased school construction.

[7] Accessibility requirements would typically apply also to temporary modular classroom units.

Labels:

Design,

Project Administration,

Project Management

Wednesday, November 23, 2011

A Few Predictors of Building Failure in New Construction

The following suggested predictors of building failure in new construction are based on years of experience tracing building failures to their causes. While the failures may express themselves as discrete detail flaws, underlying causes are often found in contractual decision making, project administration and management, and in conceptual design. The following predictors do not guarantee building failure, but they do indicate a heightened risk of failure.

- Building from Schematic Design or other preliminary design documents – Schematic Design Drawings or other preliminary drawings that are prepared in CAD or a related computer program can appear quite precise, so it is possible to mistakenly expect such drawings to be sufficient for construction. Schematic Design Drawings typically lack sufficient detail for construction and may not be well conceived in terms of how materials and building components relate to one another. There is a high risk of building performance problems, including but not limited to building envelope leaks, when Schematic Drawings or other preliminary drawings are used as the basis of construction.

- Eliminating or drastically limiting the Architect’s role during construction – If the Architect is dismissed from the construction phase of a project, or if the Architect’s services are reduced below the standard of practice in order to save cost or expedite construction, there is a heightened risk that changes and substitutions will be made without the review and scrutiny of the Architect, who would be expected to consider the compatibility of changes and substitutions with the design intent or even with code requirements and is expected to know more than contractors do about these matters. (Similar problems can occur if the Architect’s construction administration services are delegated to inexperienced staff, who may not have sufficient knowledge about the materials and systems they encounter on the construction site.)

- Insufficient consideration of climate and weather – Success of building designs and design features in one climate are not good predictors of success in a different climate. This is true for building envelope designs in different geographic locations, and it is true for interior design features, materials, and details that are mistakenly used in exterior applications where they are inadequate for exposure to weather, including precipitation and exterior variations in temperature. It is also true for moisture sensitive interior materials that are subjected to high humidity related to building use (e.g., a swimming pool environment).

- Assuming that the selection of an innovative, energy efficient product or system will, on its own, lead to a durable, energy efficient building – Examples include rot failures related to SIP (structural insulated panel) construction where panel joints were not properly sized and sealed and where OSB facing material was exposed to moisture in the belief (espoused by the panel manufacturer) that OSB was a waterproof material that need not be protected from moisture.

Certainly, there can be other predictors of building failure in new construction, and avoiding the predictors above may not lead to a trouble free building every time. Still, the issues above appear to be common enough to warrant their listing as predictors of building failure.

Tuesday, November 22, 2011

Planning for Concealed Site Conditions

Discovery of concealed site conditions can raise havoc with a project, possibly disrupting the construction schedule and adversely impacting the project budget. Here's a link to an article I wrote a few years ago to share some of my experience with concealed site conditions: Planning for Concealed Site Conditions

Monday, November 21, 2011

Delegating for Architects

Project results are directly related to the effectiveness of project communications. Successful delegation of responsibilities and tasks depends on effective communication. Download "Delegating for Architects" to read more about this.

Thursday, September 29, 2011

Value Engineering

Any discussion of value engineering (V.E.) is likely to produce a rush of criticisms of the process if you work in an architecture or engineering practice. The architects and engineers are likely to recall bad experiences when V.E. was started late, approaching or following the completion of construction documents, at a time when the project schedule did not allow sufficient time to fully consider consequences and implement V.E. changes in a comprehensive and well coordinated manner. They are likely to complain that "V.E. stripped the value out of the project."

A better approach to V.E. is to start it earlier, when material and system decisions are being formulated and before a lot of time is invested in developing applicable details and specifications.

The Whole Building Design Guide (http://www.wbdg.org/resources/value_engineering.php) offers an excellent synopsis of V.E. and a clear picture of the advantages of doing it earlier in the life of a project.

A better approach to V.E. is to start it earlier, when material and system decisions are being formulated and before a lot of time is invested in developing applicable details and specifications.

The Whole Building Design Guide (http://www.wbdg.org/resources/value_engineering.php) offers an excellent synopsis of V.E. and a clear picture of the advantages of doing it earlier in the life of a project.

Sunday, November 1, 2009

Manage Design Costs with Early Project Overtime

One of Mike's PM tips for managing design costs on a project: "If you know you are going to have to work overtime on a project," he said, "do it in the beginning. It costs less to do overtime when there are only one or two people working on a project." (See Purposeful chaos (the 2-minute design offense))

This makes a lot of sense when considering a project on a compressed time line. If you're trying to figure out how to get all the work done in a short period of time, the least attractive alternative is having an army of designers and drafters burning the midnight oil and generating design questions as the completion deadline approaches. Eleventh hour overtime can quickly burn through budgeted hours and fee dollars, and too many new or unanswered questions at that stage can lead to unplanned chaos.

It's also interesting to consider how this principle of early overtime might benefit progress and labor costs on a construction site. Early trades - like earthwork, concrete, and steel - set the stage for a larger work force, and trades can multiply as the project becomes ready for their work.

This makes a lot of sense when considering a project on a compressed time line. If you're trying to figure out how to get all the work done in a short period of time, the least attractive alternative is having an army of designers and drafters burning the midnight oil and generating design questions as the completion deadline approaches. Eleventh hour overtime can quickly burn through budgeted hours and fee dollars, and too many new or unanswered questions at that stage can lead to unplanned chaos.

It's also interesting to consider how this principle of early overtime might benefit progress and labor costs on a construction site. Early trades - like earthwork, concrete, and steel - set the stage for a larger work force, and trades can multiply as the project becomes ready for their work.

Labels:

Project Administration,

Project Management

Friday, May 22, 2009

Construction Documents Coordination Matrix

It may look a little "geeky", but this matrix can be an effective tool for considering interdisciplinary coordination needs. The design disciplines for a project are listed across the top and down one side. The intersection points represent coordination between disciplines (e.g., between Civil/Site and Electrical). Seeing the possibilities in this format can help to minimize coordination gaps. On a given project, the extent and specifics of coordination will differ from point to point, and the design displines may also differ. Still, seeing an intersection point can prompt thoughts about needed coordination between any two disciplines. For example, where Civil/Site meets Foodservice, it may bring to mind the need to coordinate the locations of exterior condensing units with site work. Etc. Etc. Etc.

Looking at this coordination matrix, it is also easy to see how extensive coordination really is (and must be) on an architectural project. On some complex projects, coordination can be seen as a full time job in itself, from the coordination of consulting agreement scopes of work to the coordination of sub-trade scopes of work and the dotting of i's and crossing of t's in construction documents.

Wednesday, May 6, 2009

Email is Snail Mail for some

We all have our preferred means of communication, and we are inclined in this digital age to think that faster is better. But, in some situations, exclusive use of lightning speed technology may actually delay communication. The growing popularity of email years ago gave rise to the derogatory term "snail mail" to describe older and slower postal service or even "express" systems for delivery of hard copy mail.

But, for some, "snail mail" still beats email. In one situation an executive who touts his company's use of computer based technology remains reluctant to make personal use of it. Sending this CEO an email message actually guarantees as much as a 2-week communication delay. His orders to his assistant - who actually receives his email - is to print it all out once every two weeks and put it into his in-box in a neat stack. He may then read it along with letters, magazines, advertisements, and other mail.

This may seem like an extreme case these days, but it illustrates the importance (and advantage) of utilizing several means of communication to deliver a message. Don't forget face to face conversation, the telephone, the postage stamp, arm waving, signing, the bullhorn, and other potentially effective ways to deliver a message. (See also Practice the Hand-off.)

But, for some, "snail mail" still beats email. In one situation an executive who touts his company's use of computer based technology remains reluctant to make personal use of it. Sending this CEO an email message actually guarantees as much as a 2-week communication delay. His orders to his assistant - who actually receives his email - is to print it all out once every two weeks and put it into his in-box in a neat stack. He may then read it along with letters, magazines, advertisements, and other mail.

This may seem like an extreme case these days, but it illustrates the importance (and advantage) of utilizing several means of communication to deliver a message. Don't forget face to face conversation, the telephone, the postage stamp, arm waving, signing, the bullhorn, and other potentially effective ways to deliver a message. (See also Practice the Hand-off.)

Friday, April 24, 2009

Architectural Design: CAD doesn't care

CAD (computer aided design) is a wonderful tool, but it is often credited with attributes that it does not possess. CAD does not care if a picture drawn by an operator is incomplete or nonsensical. It does not care if structural plans and architectural plans for the same building are based on different dimensions that should instead be the same. It does not care if a column is missing or if a mechanical duct encroaches into building occupants' headroom. It does not care if the roof slopes away from the roof drains. It does not care if there is no flashing or if the building leaks. It does not care if exterior grade is above a window sill. It does not care if the building is uncomfortable or if mechanical equipment has no electrical connections. It does not care if wheelchair users cannot get through a door or down a hallway or if building occupants cannot safely exit the building. It does not care if a building is energy efficient. CAD is a wonderful tool, but "caring" is not one of its attributes.

Labels:

Project Administration,

Project Management

Saturday, April 18, 2009

Value Engineering can add value

Architects and engineers may be used to thinking of Value Engineering as a form of design torture, where value is stripped out of a project design in order to save money. But Value Engineering can also provide an opportunity to consider values that may enhance the performance of a building over time. It is a good time to consider or revisit questions of maintainability, access for maintenance, and flexibility for changing uses over time. One use change that is common but rarely considered is the conversion of non-storage spaces to storage use; this is often done informally by building users and without consideration for the capacity of the floor or other supporting structure that is being loaded. In some cases the structural capacity of a floor can be increased by including additional floor joists and reducing the spacing between them, and the initial additional cost may be minimal for a substantial gain in flexibility. (Storage uses may also bring other requirements that should be considered in making the decision.)

Labels:

Project Administration,

Project Management

Friday, April 17, 2009

It takes timely money to make a project go

A project owner was feeling frustrated that the contractor, who was doing work of good quality, was not going fast enough. Considering the contractor's monthly application for payment, the owner decided to not pay the contractor for the previous month's work in the hopes that the decision would cause the contractor to work faster. Instead, the contractor's work slowed to a crawl as the contractor's employees and subcontractors stayed away from the project. Subsequently, the contractor submitted a delay claim against the owner. The owner also heard that work on another project in the area had sped up during the same period of time.

A different owner on a different project was not satisfied with the quality of part of the work done by the project's contractor, but chose to pay the contractor for that work anyway, hoping the contractor would correct it. Instead, the contractor proceeded with other work, making correction of the unsatisfactory work less practical and more costly. When the owner complained to the contractor about the contractor's failure to correct the unsatisfactory work, the contractor pointed out that the owner had paid for it, so the contractor considered it complete and thought the owner did, too. The following month, the owner withheld part of the contractor's payment to cover the cost of correcting the previous unsatisfactory work. Then construction progress was slowed by a delay in delivery of materials of approximately the same value as the payment amount withheld by the owner. The material supplier had furnished similar materials for several other projects done by the same contractor, and delivery for this project was contingent on the supplier's receipt of payment for a previous project.

During a very busy construction boom, a project owner decided to make advance payment to the project's contractor as an incentive to get construction started on his project. Then several weeks passed without any construction activity on the project. When the owner complained about the situation to a friend who had been a project owner during a previous recession, the friend told him he had done the same thing to help a contractor get that project started during the recession - and the result was the same.

It takes money to make a project go, but payment at the wrong time can be counterproductive.

A different owner on a different project was not satisfied with the quality of part of the work done by the project's contractor, but chose to pay the contractor for that work anyway, hoping the contractor would correct it. Instead, the contractor proceeded with other work, making correction of the unsatisfactory work less practical and more costly. When the owner complained to the contractor about the contractor's failure to correct the unsatisfactory work, the contractor pointed out that the owner had paid for it, so the contractor considered it complete and thought the owner did, too. The following month, the owner withheld part of the contractor's payment to cover the cost of correcting the previous unsatisfactory work. Then construction progress was slowed by a delay in delivery of materials of approximately the same value as the payment amount withheld by the owner. The material supplier had furnished similar materials for several other projects done by the same contractor, and delivery for this project was contingent on the supplier's receipt of payment for a previous project.

During a very busy construction boom, a project owner decided to make advance payment to the project's contractor as an incentive to get construction started on his project. Then several weeks passed without any construction activity on the project. When the owner complained about the situation to a friend who had been a project owner during a previous recession, the friend told him he had done the same thing to help a contractor get that project started during the recession - and the result was the same.

It takes money to make a project go, but payment at the wrong time can be counterproductive.

Wednesday, April 15, 2009

The Schedule of Values deserves close attention

On public building construction projects (and, possibly, on most private building projects) the contractor develops a Schedule of Values that forms the basis for monthly applications for payment (also known as "requisitions") that will be submitted as construction proceeds. The Schedule of Values is typically submitted for architect and owner review at the beginning of the construction project and well before the first regular application for payment will be submitted. When reviewing the contractor's proposed Schedule of Values, it is important to consider the meaning of the specific line item descriptions on the schedule and to also consider the architect's and owner's ability to assess progress on those discrete parts of the project as applications for payment are submitted by the contractor.

The meanings of the line items may seem simple enough at first glance, but they have been known to be interpreted differently by subcontractors, contractors, architects, engineers, and owners as construction proceeds. Site work items seem to be uniquely subject to varying interpretation. The intent of terms like "Excavation", "Cuts and Fills", "Fill", and others are good agenda items for a meeting to discuss a proposed Schedule of Values. For the architect and owner who will be assessing the value of periodic progress on a given item, it is especially important to understand what is included in the line item and what is not included - in part to avoid a possible disagreement as construction proceeds. "I think the owner already paid for that in this item," says the architect. "Oh, no," says the contractor or the sub. "That was never in that item. It was in this other item."

The architect's and owner's ability to assess progress on the listed work items also depends on the monetary amount of the particular item. It is common to require a contractor to break down items that are too large (e.g., Site Work $2,000,000) into smaller items (e.g., Rough Grade south yard: $15,000, Fine Grade west field: $7,500, etc.) that are more easily assessed and add up to the total value of site work. For some, the rule has been to break down the schedule into items no greater than $20,000 in value. That may not be a practical rule to follow in every case, but it is important to consider the ability of the observer to assess progress that is claimed on a given application for payment while avoiding confusion with other work that may be similar or within the same trade. Contractors and subcontractors are usually quite interested in receiving prompt payment for completed work, so it follows that they should be willing to invest time in the beginning of a project to establish a common understanding of the items in the Schedule of Values.

Another rule, sometimes challenged, is that once the Schedule of Values is established, it should not be changed. That's a good rule (with a notable exception that sometimes a more detailed breakdown of an established item may become necessary in order to assess progress and determine appropriate payment). And there are other rules....

The meanings of the line items may seem simple enough at first glance, but they have been known to be interpreted differently by subcontractors, contractors, architects, engineers, and owners as construction proceeds. Site work items seem to be uniquely subject to varying interpretation. The intent of terms like "Excavation", "Cuts and Fills", "Fill", and others are good agenda items for a meeting to discuss a proposed Schedule of Values. For the architect and owner who will be assessing the value of periodic progress on a given item, it is especially important to understand what is included in the line item and what is not included - in part to avoid a possible disagreement as construction proceeds. "I think the owner already paid for that in this item," says the architect. "Oh, no," says the contractor or the sub. "That was never in that item. It was in this other item."

The architect's and owner's ability to assess progress on the listed work items also depends on the monetary amount of the particular item. It is common to require a contractor to break down items that are too large (e.g., Site Work $2,000,000) into smaller items (e.g., Rough Grade south yard: $15,000, Fine Grade west field: $7,500, etc.) that are more easily assessed and add up to the total value of site work. For some, the rule has been to break down the schedule into items no greater than $20,000 in value. That may not be a practical rule to follow in every case, but it is important to consider the ability of the observer to assess progress that is claimed on a given application for payment while avoiding confusion with other work that may be similar or within the same trade. Contractors and subcontractors are usually quite interested in receiving prompt payment for completed work, so it follows that they should be willing to invest time in the beginning of a project to establish a common understanding of the items in the Schedule of Values.

Another rule, sometimes challenged, is that once the Schedule of Values is established, it should not be changed. That's a good rule (with a notable exception that sometimes a more detailed breakdown of an established item may become necessary in order to assess progress and determine appropriate payment). And there are other rules....

Saturday, April 11, 2009

Ask the right person or get the wrong answer

We were working on a fast-track office building project. The project duration was 6 months and 4 days from the start of design to owner occupancy. It was a 4-story, 125,000 sq. ft. office building to be built on deep friction piles in very deep silt. Construction started while we were sharpening our pencils. We expected questions from the contractor, and the contractor's personnel were aggressive in pursuing the information they needed to advance the project toward the ambitious substantial completion date. Contractors may learn from some school of practice that they should call the highest authority in order to get the information flowing (a.k.a. rattle the highest cage). In this case, the contractor's junior project manager made it a practice to bypass the architect and structural engineer and to call the developer's representative for the smallest detail of information, like embedment length of anchor bolts.........important, for sure, but an annoying subject for a developer's representative who has just negotiated a $7 million deal for his employer and his client. The developer's representative quickly tired of receiving such phone calls from the contractor's junior project manager. One day, in response to the project manager's phone call, he said, "Don't call me again..........for the rest of your life."

Wednesday, April 8, 2009

Monitoring construction progress

One effective way to monitor progress on a construction project is to consider cumulative payments to the contractor or claimed percent complete against an estimated payment schedule that should be established at the start of the project. In most cases the estimated schedule of cumulative payments or percent complete should look like an 'S' curve, similar to the one in the diagram above. It is likely to be relatively flat at start-up, due in part to the limited number of trades that can work on the project at first. As the project advances, progress allows the addition of trades (and workforce), indicated by the steeper line in the middle of the 'S' curve. The flatter tail end of the project represents a reduced workforce, fewer trades, finishing details, and punch-list work.

If actual progress looks much different than the 'S', the project may be headed for trouble. For example, a prolonged flat period at the beginning (or a shallower slope on the steeper part of the 'S' as shown by a dashed tangent line above) may forecast a late project completion. Alternatively, if requested payments suggest a steeper curve earlier in the project, the requested payments could be exaggerating actual progress, and one bad result could be releasing too much money too early and not holding enough funds to complete the project. The 'S' curve should not be considered an absolute measure of progress, but it can be an effective tool for comparison and forecasting.

[Note that a similar approach can be used for looking at design progress. See Staffing a design project.]

Tuesday, April 7, 2009

Why we need to manage architectural projects

Everyone has an agenda. If we don't manage the projects, they may be managed by individual interests like the following.

- "I already know what I'm going to do. Just tell me when to start."

- "I'm here to draw. I'm not interested in any program information."

- "I'm only going to do what I'm told, nothing else."

- "Finally, a chance to demonstrate my design prowess!"

- "I think we should use those windows that were presented to us at the last Lunch-n-Learn. Wasn't that a great tart?"

- "This is not a linear process. It takes as long as it takes."

- "I'm not going to let Jim ruin another project."

- "We never meet the budget, and we never finish on time. It's not my fault. That's just the way it is. Why can't you get that?"

- "Someone has to tell the owner to butt out. We already know what they need."

- "I don't mind attending a few meetings, but I'm not actually going to start doing any engineering work until I know the architect has stopped screwing around with the plan. I'm not getting enough fee to spend engineering time on design refinements."

- "We're going to do the whole project with our standard details."

- "Hey! It will be really cool if we tilt the walls over like this so they look like a roof but will still be made of wall materials. I wonder if it will keep the water out. Maybe it won't rain much. We can specify really good sealant. Maybe it will be okay this time."

- "Green? I'm not going to say it in these words out loud, but I refuse to be held accountable for any guinea pig design experiments or systems. Therefore, I'm going to do exactly the same thing I've done for the last 20 years. It's all going to be off the shelf. I don't want any call-backs on this project. That's what I call efficiency."

- "I will be calling all the shots. Period."

Labels:

Project Administration,

Project Management

Thursday, April 2, 2009

A notable roof warranty exclusion

Manufacturers of single ply roofing membranes offer warranties that vary in duration and conditions of coverage. The warranties typically include a lengthy list of requirements and exclusions. One of the most notable exclusions, which appears in all caps and/or boldface type on some warranties, is a statement that excludes representations or promises made by a representative of the manufacturer which differ from the provisions of the published warranty.

The 'sales rep' exclusion highlights a common dilemma. The manufacturer's sales rep typically has to please several "masters". The rep has to please the architect and project owner in order to get the manufacturer's product or system specified. Then the rep has to please the roofing contractor, the first-line customer who will actually purchase and pay the manufacturer (or distributor) for the product. And, of course, the rep has to please the manufacturer with productive sales. In construction, full payment usually follows installation, so the manufacturer's rep may be involved in site visits, inspections, and warranty processing related to project completion. In order to get paid upon project completion, the rep has to pursue the satisfaction of all these parties - the roofing contractor, the architect, the owner, the manufacturer, and maybe even a few others. That may be a tall order under circumstances where the interests of those parties are not all aligned, and one outcome may be a promise that cannot be kept. The 'sales rep' exclusion suggests that manufacturers have had experience with reps making promises that are contrary to the terms of a published warranty, and the exclusion protects the manufacturers from that problem.

Considering again the question "Who is the customer?", I recall a conversation with a manufacturer's rep several years ago. We were concerned with the quality of work that was being done by a roofing contractor, and we thought the manufacturer's rep might be able to help persuade the roofing contractor to do a better job. The rep's response to our request was very enlightening: "I can't really help you out with that," he said. "The roofing contractor is my customer."

The 'sales rep' exclusion highlights a common dilemma. The manufacturer's sales rep typically has to please several "masters". The rep has to please the architect and project owner in order to get the manufacturer's product or system specified. Then the rep has to please the roofing contractor, the first-line customer who will actually purchase and pay the manufacturer (or distributor) for the product. And, of course, the rep has to please the manufacturer with productive sales. In construction, full payment usually follows installation, so the manufacturer's rep may be involved in site visits, inspections, and warranty processing related to project completion. In order to get paid upon project completion, the rep has to pursue the satisfaction of all these parties - the roofing contractor, the architect, the owner, the manufacturer, and maybe even a few others. That may be a tall order under circumstances where the interests of those parties are not all aligned, and one outcome may be a promise that cannot be kept. The 'sales rep' exclusion suggests that manufacturers have had experience with reps making promises that are contrary to the terms of a published warranty, and the exclusion protects the manufacturers from that problem.

Considering again the question "Who is the customer?", I recall a conversation with a manufacturer's rep several years ago. We were concerned with the quality of work that was being done by a roofing contractor, and we thought the manufacturer's rep might be able to help persuade the roofing contractor to do a better job. The rep's response to our request was very enlightening: "I can't really help you out with that," he said. "The roofing contractor is my customer."

Tuesday, March 24, 2009

Roof Shingle Warranty: What's in it?

There may be a popular notion that a 30-year shingle is one that comes with a full 30-year warranty against leaks, so that if you (or, more likely, your building) experience a roof leak, say, 27 years from the date of installation, you can call the shingle manufacturer, and someone will re-roof your building at no cost to you. Wish it were so!

One widely known shingle manufacturer has produced a lengthy warranty that, based on my review, does not even include the word "leak". It warrants shingle "performance", but for that manufacturer, performance is apparently not related to the possibility of leaks.

Although there are numerous shingle manufacturer warranties and options available, the basic warranty, even for a "30-year" shingle, covers labor and materials to replace shingles that are proven to have significant manufacturing defects within a more limited period of time (like 2 to 10 years from manufacture or installation). After that the cost of labor is excluded, and the cost of shingle material is pro-rated based on the expected life of the shingle. Other exclusions are numerous. Tear off, disposal, replacement of flashing and other accessories are typically excluded, as are shingle replacement in cases where installation was not completed in accordance with the manufacturer's recommendations or where ventilation is not adequate. Under some circumstances a reduced limited warranty may be available from at least one manufacturer for shingles installed over insulated roof sheathing or vented, insulated sheathing. Perhaps the most notable of all exclusions: the warranty does not cover damage to the inside of your house and your furniture and other belongings.

Other cautions: At least one manufacturer recommends open metal valleys and will not generally provide warranty coverage for shingles installed in closed (woven or close-cut) valleys. Shingle warranties are typically transferable once from the initial owner of a roof to a subsequent owner with proper notification and paperwork and, in some cases, payment of a warranty transfer fee, all within a period of time stipulated in the warranty. Warranties against wind blow-off are also qualified to exclude circumstances where weather or temperature conditions or roof orientation have not or do not allow for the self-sealing adhesive strips to seal; and that can take months or maybe longer. And limited warranties for algae resistance are available for some shingles - you may qualify for limited financial assistance to pay for algae removal.

Still not satisfied? With some shingles you can get a lifetime warranty - that is, the shingle is warranted for the life of the original purchaser. However, that too is pro-rated after an initial period of maximum coverage. And, when you depart, it may automatically convert to a 50-year warranty for your survivors. Wow! Does that give you peace of mind?

The normal disclaimer applies: Read the fine print in your shingle warranty to see how it applies to you and your circumstances.

Finally, don't forget that the spaces around and between the shingles are not usually covered by a shingle warranty.

One widely known shingle manufacturer has produced a lengthy warranty that, based on my review, does not even include the word "leak". It warrants shingle "performance", but for that manufacturer, performance is apparently not related to the possibility of leaks.

Although there are numerous shingle manufacturer warranties and options available, the basic warranty, even for a "30-year" shingle, covers labor and materials to replace shingles that are proven to have significant manufacturing defects within a more limited period of time (like 2 to 10 years from manufacture or installation). After that the cost of labor is excluded, and the cost of shingle material is pro-rated based on the expected life of the shingle. Other exclusions are numerous. Tear off, disposal, replacement of flashing and other accessories are typically excluded, as are shingle replacement in cases where installation was not completed in accordance with the manufacturer's recommendations or where ventilation is not adequate. Under some circumstances a reduced limited warranty may be available from at least one manufacturer for shingles installed over insulated roof sheathing or vented, insulated sheathing. Perhaps the most notable of all exclusions: the warranty does not cover damage to the inside of your house and your furniture and other belongings.

Other cautions: At least one manufacturer recommends open metal valleys and will not generally provide warranty coverage for shingles installed in closed (woven or close-cut) valleys. Shingle warranties are typically transferable once from the initial owner of a roof to a subsequent owner with proper notification and paperwork and, in some cases, payment of a warranty transfer fee, all within a period of time stipulated in the warranty. Warranties against wind blow-off are also qualified to exclude circumstances where weather or temperature conditions or roof orientation have not or do not allow for the self-sealing adhesive strips to seal; and that can take months or maybe longer. And limited warranties for algae resistance are available for some shingles - you may qualify for limited financial assistance to pay for algae removal.

Still not satisfied? With some shingles you can get a lifetime warranty - that is, the shingle is warranted for the life of the original purchaser. However, that too is pro-rated after an initial period of maximum coverage. And, when you depart, it may automatically convert to a 50-year warranty for your survivors. Wow! Does that give you peace of mind?

The normal disclaimer applies: Read the fine print in your shingle warranty to see how it applies to you and your circumstances.

Finally, don't forget that the spaces around and between the shingles are not usually covered by a shingle warranty.

Labels:

Gosh Darnit,

Project Administration,

Roofing

Monday, March 23, 2009

Soliciting Bids for Architectural Services?

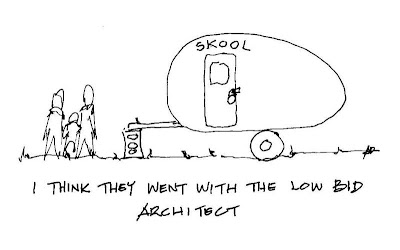

Soliciting bids for architectural services carries a lot of risk. The main risk is that the party soliciting the bids may not understand the services and may not establish the scope of work sufficiently to be able to realize desirable results from all the architects who may decide to submit bids. If lowest price governs the selection, then the result may be reduced services - less than what is needed for your project. As the client, you may not have the input that you need to have in the design process. During construction, you may not have the attention (construction administration services) that you need from the architect to reasonably determine a contractor's progress and compliance with construction document requirements. In the end, you may not have a completed project that meets your needs. Consider the school above that resulted from soliciting bids for architectural services.

A qualification-based selection process is likely to produce better services, a better experience for the client, and better results.

Labels:

Gosh Darnit,

Project Administration

Subscribe to:

Posts (Atom)